6690 ColdFuze Crack Sealer

6690 ColdFuze Crack Sealer

Unleash the power of innovation in pavement maintenance with Perma-Patch 6690 ColdFuze Black, the first cold-pour crack sealant engineered to meet the rigorous ASTM D6690 specifications traditionally reserved for hot-applied products.

This groundbreaking, single-component sealant is designed for efficiency and superior performance, making it an essential choice for government road maintenance departments and paving contractors alike.

Crack Sealing Reinvented

Quick & Easy To Use

Reliable

Cost Saving

Product Highlights:

Key Benefits:

Testimonials:

Public Works Director | City of Brentwood

“ColdFuze has provided us the ability to have a scalable crack-filling program without a costly distributor/kettle and the time needed to heat it up, maintain it, clean it, etc.

The Perma-Patch team has been very helpful in educating us and supplying us with what we need. We have been very impressed with the ColdFuze product so far.

We are able to address many of our own cracks without the costly equipment or being beholden to a contractor’s schedule.”

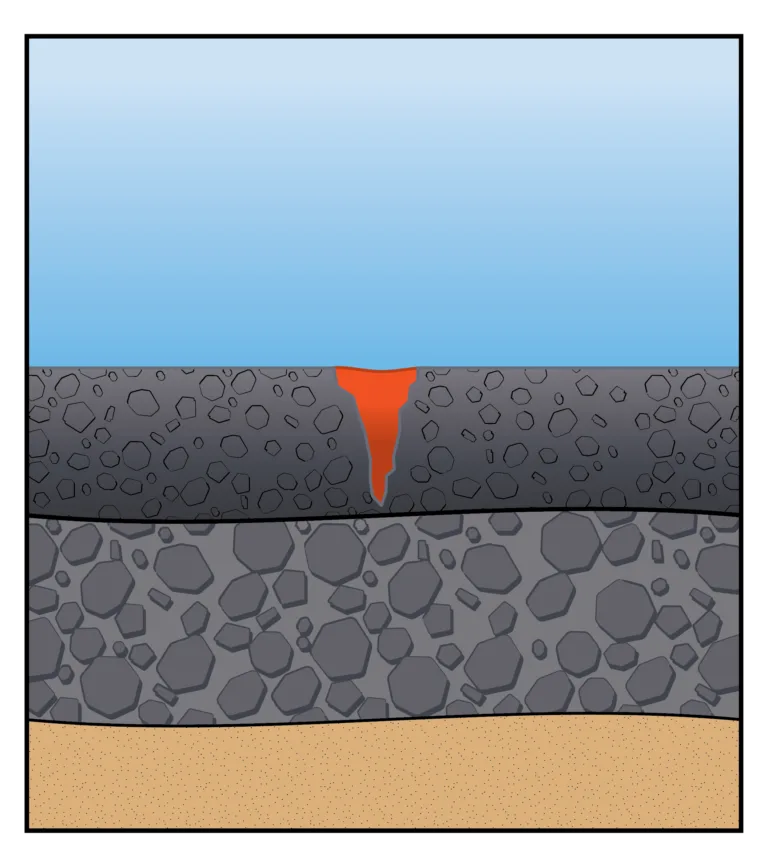

Application Made Simple:

Preparing the pavement is straightforward – ensure cracks are clean and dry to achieve an optimal bond. 6690 ColdFuze Black can be applied using a nozzle for precision, or poured and spread with a squeegee or disk tool, ensuring complete coverage and protection.

Choose Perma-Patch 6690 ColdFuze for a more efficient, safer, and cost-effective solution in pavement maintenance. Revolutionize your approach to road and highway preservation, ensuring longevity and reliability with every application. Perma-Patch 6690 ColdFuze – where technology and efficiency pave the way for the future.

Two Color Options:

Frequently Asked Questions:

Chat with AI Assistant

>