When it comes to Gator-Aid® and Black Fill®, the right finish starts with the right tool. Neoprene squeegees aren’t just an accessory—they’re essential to achieving the smooth, consistent results these materials are designed for.

This guide breaks down exactly how to select, use, and maintain squeegees that deliver field-proven results across asphalt repair jobs of all sizes.

Why Squeegee Choice Matters

A properly selected neoprene squeegee does more than spread material—it controls finish quality, prevents waste, and ensures material builds to the correct wet film thickness.

Flexible Blade Dynamics

A 70–72 durometer neoprene blade flexes enough to ride pavement texture smoothly, avoiding skips or chatter that lead to poor coverage.

Chemical Resistance

Neoprene resists oils, water, and sealant additives found in asphalt materials, maintaining its shape and effectiveness over time.

Wet Film Control

Using the correct squeegee ensures your application stays within the recommended 1/8″ to 3/16″ wet film thickness—essential for product performance and longevity.

Product-Specific Squeegee Recommendations

Product: Black Fill®

> Tool Requirement: Flat-Blade Neoprene Squeegee

> Notes: Required for proper spread across alligator cracks

Product: Gator-Aid®

> Tool Requirement: Neoprene Squeegee or Sealcoat Broom

> Notes: Squeegee ensures smooth finish and precise control

For Black Fill®, while a sealcoat broom can be used to create a textured aesthetic finish, a neoprene squeegee is recommended for smooth feathered edges and controlled application thickness.

What to Avoid

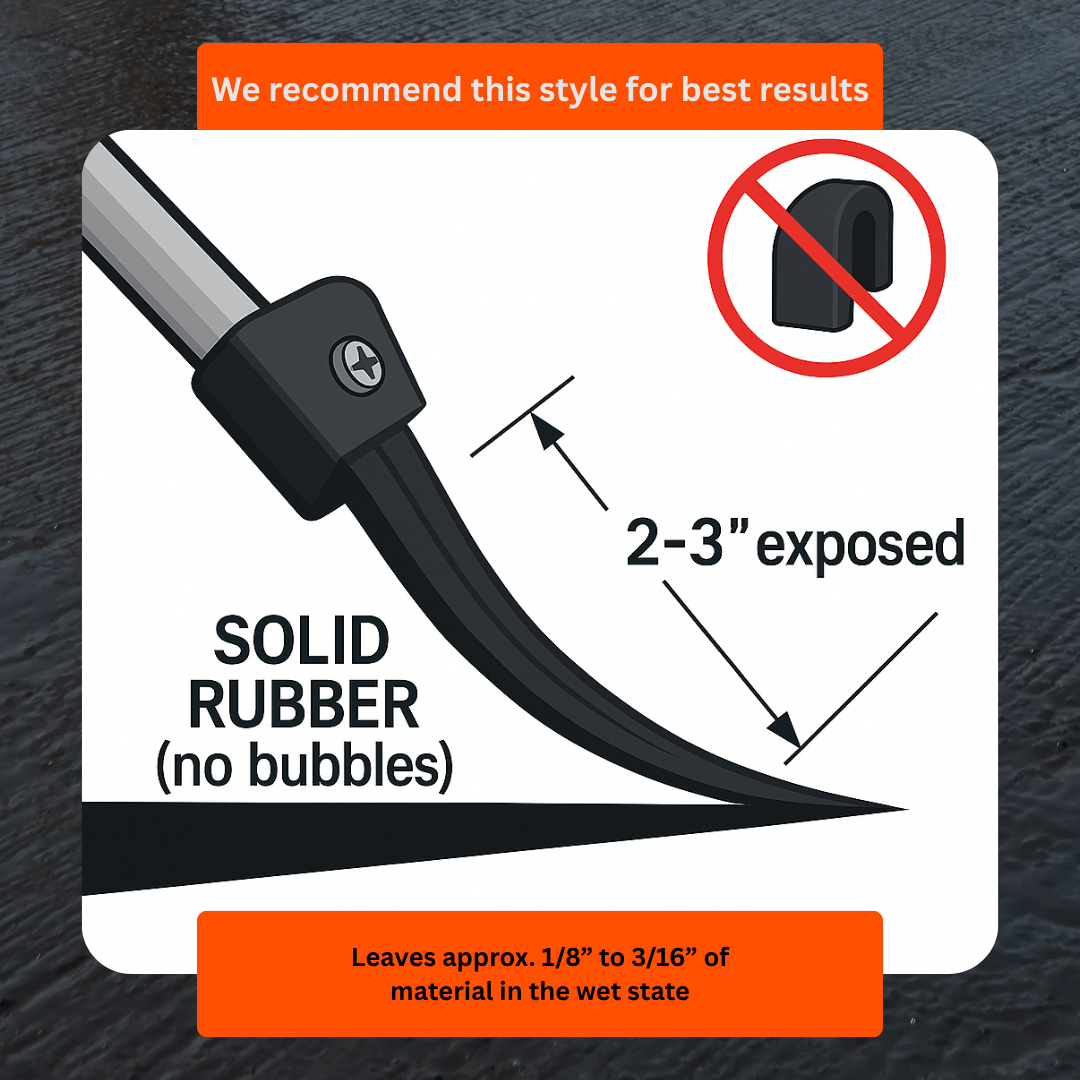

- Stiff or short rubber blades

- Expanded neoprene with air pockets

These lead to uneven surfaces, ridging, and material waste.

Field-Tested Squeegee Models

These models meet our specifications: non-foamed neoprene, 2–3″ blade exposure, and proven compatibility with asphalt sealants and patch materials.

Best Practice: Application Technique

Black Fill®

- Pour material across surface

- Use a neoprene squeegee to pull evenly and control depth

- Optional: follow with a sealcoat broom for surface texture

- Quick set: walkable in 1 hour, traffic-ready in 2

- Clean with water

Gator-Aid®

- Clear debris from surface and cracks

- Pour directly from pail

- Spread evenly with flat neoprene squeegee using steady pressure

- Overlap 1–2″ per pass

- Maintain consistent 1/8–3/16″ wet film

- One 5-gallon pail covers 20 sq ft at ¼” depth, or 80 linear feet of ½”x½” cracks

Consistent application yields optimal adhesion and finish—especially around edges, seams, and transitions.

Troubleshooting Guide

Streaks/lines

Cause: Blade too stiff or worn

Fix: Replace when nicks > 1/16″

Uneven ridges

Cause: Foamed or undersized blade

Fix: Use non-foamed neoprene squeegee, 3″ tall

Material loss

Cause: Blade held at too steep angle

Fix: Keep handle upright and not as tilted

Squeegee Maintenance Tips

- Clean with mild soap and water after each shift

- Store flat or hang to prevent blade warping

- Rotate every 4 hours of use to prevent edge curl

- Inspect weekly for durometer drop or edge damage > 1/8″

With proper care, blades can last 25,000–30,000 sq ft per job cycle.

Quick Reference

Black Fill®

Best Tool for Application: Flat neoprene squeegee

Gator-Aid®

Best Tool for Application: Neoprene Squeegee

Final Takeaways

- Use a flexible, non-foamed neoprene squeegee with 2–3 in. blade exposure

- Avoid stiff or foamed blades that skip or leave ridges

- Confirm wet film thickness to ensure proper build and performance

- Gator-Aid® and Black Fill® perform best when paired with the right tools

- Keep squeegees clean and rotated for reliable results across every job

Need help selecting the right tools or placing an order?

Contact us today for expert support.